PVC-free vinyl is a popular choice for laser cutting projects due to its versatility and safety advantages. This guide will explore everything you need to know about PVC-free vinyl for laser cutting, from its benefits and applications to tips and techniques for achieving professional results.

Understanding PVC-Free Vinyl

PVC-free vinyl, also known as polyurethane (PU) vinyl, is a synthetic material that offers a fantastic alternative to traditional polyvinyl chloride (PVC) vinyl. It’s made without harmful chlorine and plasticizers like phthalates, making it a safer and more environmentally friendly option. This is especially important for laser cutting, as PVC releases toxic fumes when heated.

Why Choose PVC-Free Vinyl for Laser Cutting?

PVC-free vinyl boasts several advantages that make it ideal for laser cutting:

- Safety: The absence of chlorine and phthalates means no toxic fumes are released during the laser cutting process, ensuring a healthier work environment.

- Versatility: PVC-free vinyl can be used for a wide range of applications, from stickers and decals to stencils and apparel customization.

- Durability: It’s known for its excellent durability and resistance to tearing, making it perfect for long-lasting projects.

- Clean Cuts: Laser cutting PVC-free vinyl produces clean, precise cuts with minimal charring or melting.

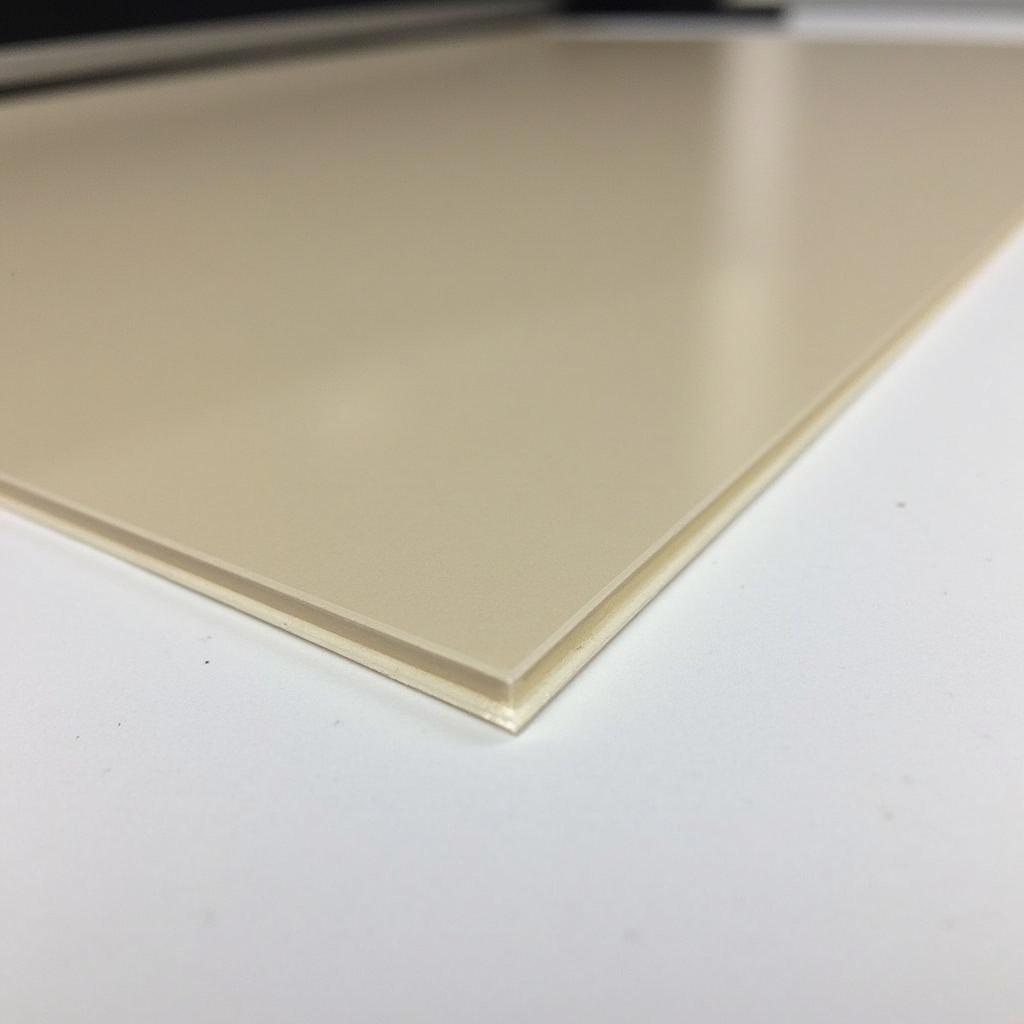

Clean Laser Cut on PVC-Free Vinyl

Clean Laser Cut on PVC-Free Vinyl

Applications of PVC-Free Vinyl for Laser Cutting

The versatility of PVC-free vinyl opens up numerous creative possibilities:

- Custom Stickers & Decals: Create personalized stickers for laptops, water bottles, or any other smooth surface.

- Apparel Decoration: Cut intricate designs for t-shirts, hoodies, and other garments.

- Stencils: Make reusable stencils for painting, etching, or other craft projects.

- Signage: Produce professional-looking signs for businesses or events.

- Home Decor: Create custom wall art, personalized coasters, and other decorative items.

Tips for Laser Cutting PVC-Free Vinyl

Achieving optimal results with PVC-free vinyl requires attention to a few key details:

- Power Settings: Adjust your laser cutter’s power settings based on the thickness and color of the vinyl. Start with lower power and gradually increase until you achieve the desired cut depth.

- Speed Settings: Similarly, adjust the speed of your laser cutter. Slower speeds are generally recommended for intricate designs.

- Ventilation: Ensure proper ventilation in your work area, even though PVC-free vinyl doesn’t release toxic fumes like PVC.

- Test Cuts: Always perform test cuts on a scrap piece of vinyl before cutting your final design. This helps you determine the optimal settings and avoid wasting material.

Laser Cutter Settings for PVC-Free Vinyl

Laser Cutter Settings for PVC-Free Vinyl

Choosing the Right PVC-Free Vinyl

When selecting PVC-free vinyl for laser cutting, consider the following factors:

- Thickness: Choose the appropriate thickness for your project. Thicker vinyl is more durable and suitable for larger projects, while thinner vinyl is better for intricate designs.

- Finish: PVC-free vinyl comes in various finishes, including matte, gloss, and glitter. Select the finish that best suits your aesthetic preferences.

- Adhesive Backing: If you’re creating stickers or decals, ensure the vinyl has an adhesive backing.

Is PVC-Free Vinyl More Expensive Than PVC Vinyl?

Typically, PVC-free vinyl is slightly more expensive than traditional PVC vinyl. However, the added cost is often justified by its safety and environmental benefits.

Conclusion

PVC-free vinyl is an excellent choice for laser cutting projects, offering a safe, versatile, and durable alternative to traditional PVC vinyl. By following the tips outlined in this guide, you can achieve professional-looking results for a wide range of applications, from custom stickers and apparel decoration to stencils and signage. Remember to always prioritize safety and test your settings before starting your project. PVC-free vinyl for laser cutting ensures a cleaner, healthier crafting experience.

FAQ

- What are the main advantages of using PVC-free vinyl for laser cutting? Safety and no toxic fumes.

- Is PVC-free vinyl suitable for all laser cutters? Generally yes, but always check your machine’s compatibility.

- What types of projects can I create with PVC-free vinyl? Stickers, decals, stencils, apparel, signage, and more.

- How do I choose the right thickness of PVC-free vinyl? Consider the size and complexity of your project.

- Where can I purchase PVC-free vinyl for laser cutting? Online retailers and craft stores.

- Can I layer different colors of PVC-free vinyl? Yes, for multi-layered designs.

- How do I clean my laser cutter after working with PVC-free vinyl? Follow your manufacturer’s instructions.

Kêu gọi hành động: Khi cần hỗ trợ hãy liên hệ Số Điện Thoại: 0972669017, Email: [email protected] Hoặc đến địa chỉ: 142 Trần Nhân Tông, Yên Thanh, Uông Bí, Quảng Ninh, Việt Nam. Chúng tôi có đội ngũ chăm sóc khách hàng 24/7.