A Free Wheeling Valve, also known as a one-way clutch, is a crucial component in various mechanical systems, allowing rotation in one direction while preventing it in the opposite. This article delves into the intricacies of free wheeling valves, exploring their functionality, applications, and benefits.

What is a Free Wheeling Valve and How Does it Work?

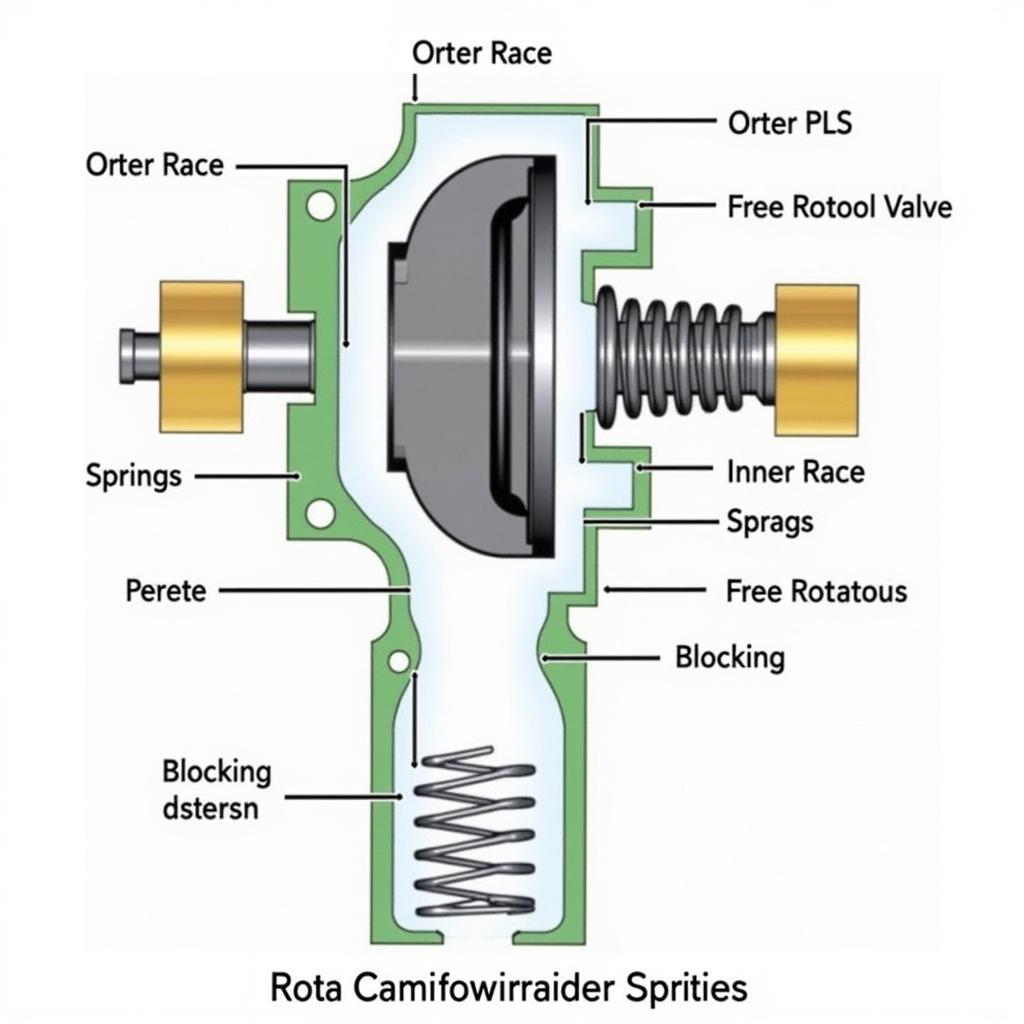

A free wheeling valve essentially acts as a mechanical diode for rotational motion. Imagine a bicycle’s rear wheel – you can pedal to move forward, but when you stop pedaling, the wheel continues to spin freely. This is the principle behind a free wheeling valve. It allows the driven shaft to rotate faster than the driving shaft or to remain stationary while the driving shaft rotates.  Free Wheeling Valve Mechanism Diagram

Free Wheeling Valve Mechanism Diagram

There are various types of free wheeling valves, each with a different internal mechanism. Common types include sprag clutches, roller clutches, and ratchet clutches. Sprag clutches use wedge-shaped elements (sprags) between two concentric races. When rotation occurs in the desired direction, the sprags lock the races together, transmitting torque. In the opposite direction, the sprags retract, allowing free rotation. Roller clutches use rollers positioned between cammed surfaces. Similar to sprag clutches, these rollers wedge and lock in one direction and release in the other. Ratchet clutches use a toothed wheel and a pawl to allow motion in one direction and prevent it in the other.

Applications of Free Wheeling Valves

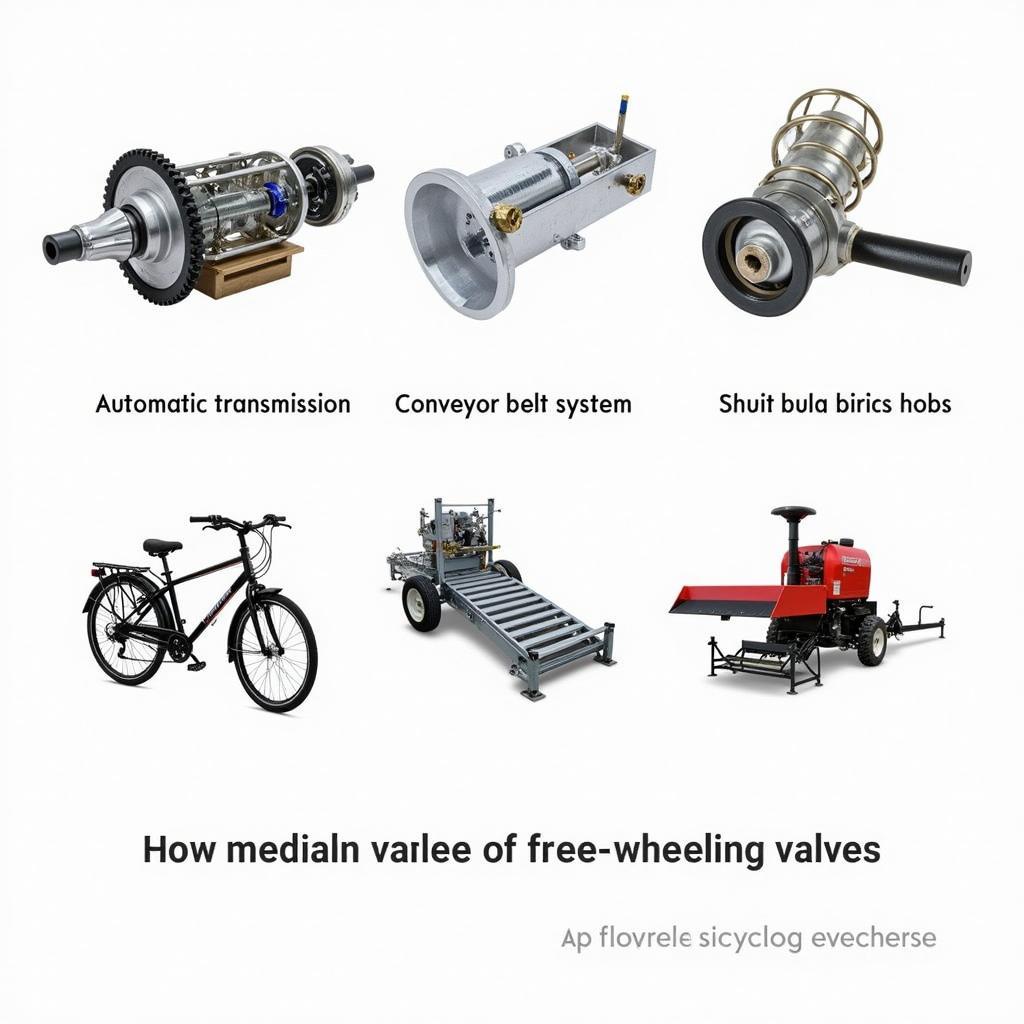

Free wheeling valves find applications in a wide range of industries and systems. Some common examples include:

- Automotive Transmissions: Overrunning clutches in automatic transmissions allow for smooth shifting and prevent engine braking when the accelerator is released.

- Material Handling: Conveyors utilize free wheeling valves to allow back-feeding or prevent reverse movement in case of power failure.

- Printing Presses: These valves enable precise indexing and control of paper movement.

- Agricultural Machinery: Used in various agricultural equipment such as harvesters and tractors to allow for smooth operation and prevent damage.

- Bicycle Hubs: Allowing the rear wheel to spin freely when the pedals are not moving.

Benefits of Using Free Wheeling Valves

Incorporating free wheeling valves into a system offers several advantages:

- Overrunning Protection: They prevent damage to equipment by allowing a driven load to overrun the driving source.

- Improved Efficiency: By decoupling the drive train in specific situations, free wheeling valves can reduce energy consumption and wear on components.

- Enhanced Safety: In some applications, they can prevent accidents by stopping reverse movement in case of equipment failure.

- Simplified Design: Free wheeling valves can simplify complex mechanical systems by replacing multiple components with a single, compact unit.

Examples of Free Wheeling Valve Applications in Different Industries

Examples of Free Wheeling Valve Applications in Different Industries

Choosing the Right Free Wheeling Valve

Selecting the appropriate free wheeling valve requires careful consideration of several factors:

- Torque Capacity: The valve must be able to handle the maximum torque of the application.

- Speed: The valve’s speed rating should be compatible with the operating speed of the system.

- Operating Environment: Factors such as temperature, humidity, and contamination should be considered when choosing materials and seals.

- Size and Mounting: The valve’s dimensions and mounting requirements must match the available space and design constraints.

Troubleshooting Common Free Wheeling Valve Issues

Sometimes, free wheeling valves may experience issues. Here are some common problems and possible solutions:

- Slipping: This could be due to wear or insufficient torque capacity. Consider replacing the valve or using a higher capacity model.

- Noise: Unusual noise could indicate damage or improper lubrication. Inspect the valve and ensure proper lubrication.

- Overheating: Excessive heat could be caused by overloading or improper installation. Check the application’s torque requirements and ensure proper installation.

“Proper selection and maintenance are crucial for maximizing the lifespan and performance of free wheeling valves,” says Dr. Emily Carter, a mechanical engineer specializing in power transmission systems.

Conclusion

The free wheeling valve is a versatile component that plays a vital role in numerous mechanical systems. Its ability to allow unidirectional rotation provides benefits such as overrunning protection, improved efficiency, and enhanced safety. Understanding its functionality and selecting the appropriate type for your specific needs are essential for ensuring optimal performance and longevity. By choosing the right free wheeling valve and implementing proper maintenance procedures, you can maximize its effectiveness and ensure the smooth operation of your mechanical system.

FAQ

- What is the difference between a free wheeling valve and a one-way bearing?

- How do I determine the correct torque capacity for my application?

- What are the common causes of free wheeling valve failure?

- How often should I lubricate my free wheeling valve?

- Can a free wheeling valve be repaired?

- What are the different types of free wheeling valves available?

- How do I install a free wheeling valve correctly?

Need further assistance? Contact us at Phone Number: 0972669017, Email: [email protected] Or visit our address: 142 Trần Nhân Tông, Yên Thanh, Uông Bí, Quảng Ninh, Vietnam. We have a 24/7 customer support team.