Oil-free Air Compressors offer a range of benefits for various applications, from powering pneumatic tools to medical and dental equipment. By choosing an oil-free compressor, you’re opting for cleaner air, quieter operation, and simplified maintenance.

Understanding Oil-Free Air Compressors

Oil-free air compressors, as the name suggests, don’t use oil in their pumping mechanism. Instead, they utilize alternative lubrication methods or specially designed components to minimize friction and heat. This results in compressed air free from oil contaminants, making them ideal for sensitive applications.

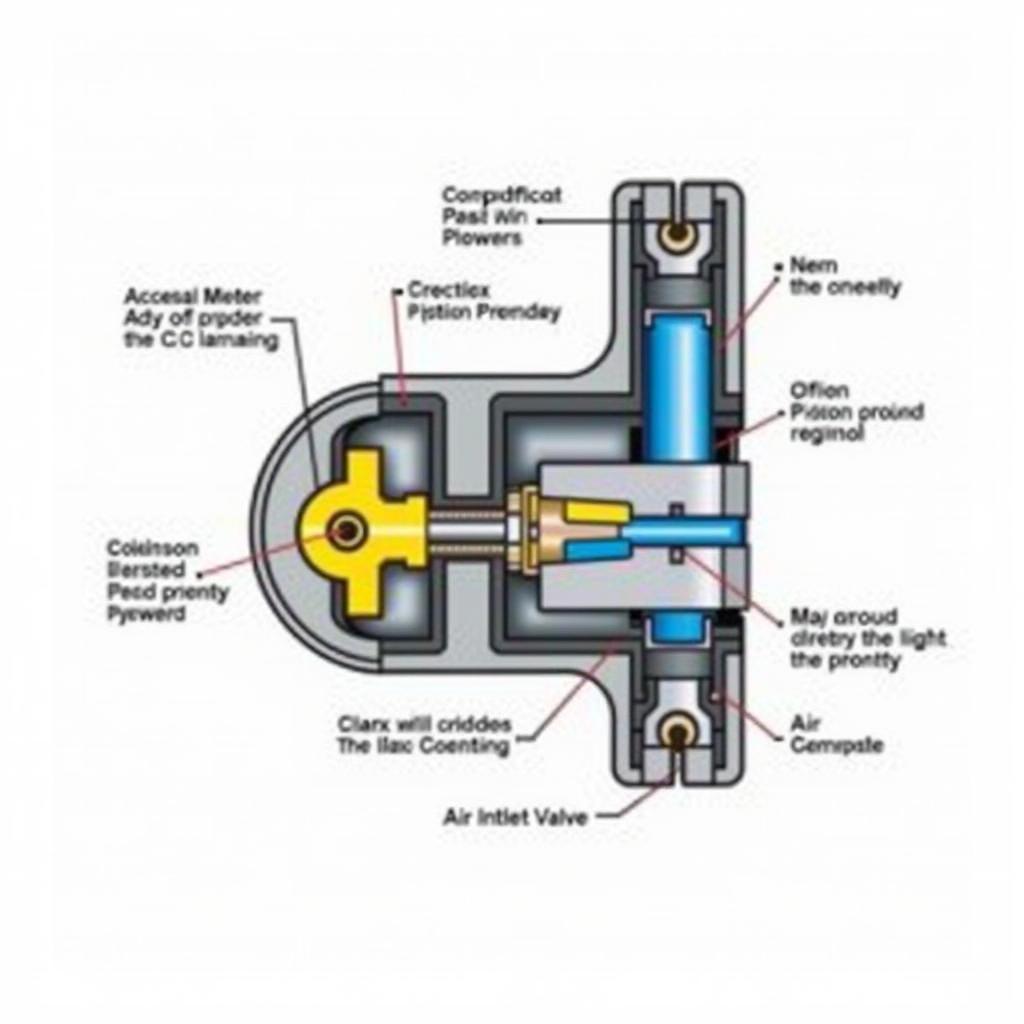

Internal components of an oil-free air compressor

Internal components of an oil-free air compressor

Benefits of Choosing an Oil-Free Air Compressor

Oil-free air compressors come with several advantages:

- Clean Air Delivery: The most significant benefit is the delivery of contaminant-free air. This is crucial for industries like healthcare, food processing, and electronics manufacturing, where even minute traces of oil can compromise product quality or safety.

- Low Maintenance: Without the need for oil changes, filter replacements, or oil disposal, maintaining an oil-free compressor becomes significantly easier and less frequent.

- Quieter Operation: Oil-free models generally operate much quieter than their oil-lubricated counterparts, making them ideal for environments where noise pollution is a concern, such as residential garages or quiet workspaces.

- Environmentally Friendly: By eliminating oil usage and disposal, oil-free compressors contribute to a cleaner environment.

Types of Oil-Free Air Compressor Technologies

There are two main types of oil-free compressor technologies:

- Oil-less Compressors: These compressors are designed with permanently lubricated components, often using Teflon or other low-friction materials. They require minimal maintenance and are suitable for light-duty tasks.

- Oil-Free Scroll Compressors: These compressors utilize two spiral-shaped scrolls to compress air. The design eliminates the need for oil lubrication in the compression chamber, resulting in completely oil-free air.

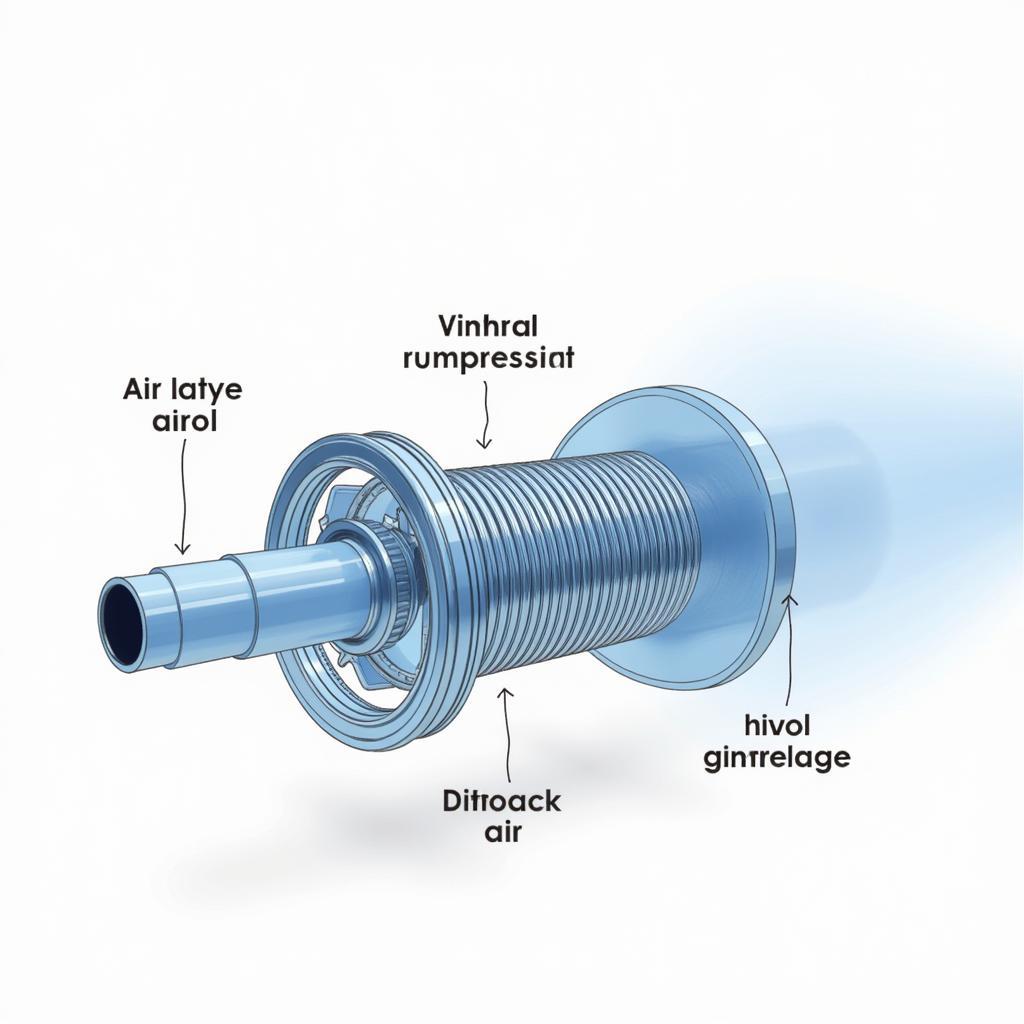

Operating mechanism of an oil-free scroll air compressor

Operating mechanism of an oil-free scroll air compressor

Applications of Oil-Free Air Compressors

The versatility of oil-free air compressors makes them suitable for a wide range of applications:

- Healthcare: From powering dental tools to operating ventilators, clean air is paramount in medical and dental settings.

- Food and Beverage Industry: Compressed air used in food processing and packaging must be oil-free to prevent contamination.

- Pharmaceuticals: Manufacturing and packaging of pharmaceuticals require a sterile environment, making oil-free compressors essential.

- Electronics Manufacturing: Oil-free air is crucial in electronics manufacturing to prevent damage to sensitive components during cleaning, spraying, or assembly processes.

Choosing the Right Oil-Free Air Compressor

Selecting the right oil-free air compressor depends on your specific needs:

- Air Quality Requirements: Determine the level of air purity required for your application. While all oil-free compressors provide cleaner air, some models offer higher levels of filtration for critical tasks.

- Air Demand: Consider the air consumption of your tools and equipment to choose a compressor with adequate CFM (cubic feet per minute) and PSI (pounds per square inch) ratings.

- Power Source: Decide between electric and gas-powered models based on your accessibility to power outlets and your portability requirements.

- Tank Size: Larger tanks offer longer run times before the compressor needs to cycle back on, while smaller tanks provide better portability.

Maintaining Your Oil-Free Air Compressor

Maintaining your oil-free air compressor is relatively simple:

- Regularly Drain the Moisture: Even though they are oil-free, these compressors still produce condensation. Draining the moisture regularly from the tank prevents corrosion and ensures optimal performance.

- Clean or Replace Air Filters: Air filters prevent dust and debris from entering the compressor. Regularly cleaning or replacing them ensures efficient operation.

- Inspect Hoses and Connections: Inspect air hoses and connections for leaks or damage. Replace worn-out components promptly to prevent air leaks and maintain pressure.

Essential maintenance tasks for an oil-free air compressor

Essential maintenance tasks for an oil-free air compressor

Conclusion

Oil-free air compressors offer a reliable and clean source of compressed air for various applications. By understanding the different types, benefits, and applications, you can make an informed decision and choose the ideal oil-free air compressor for your specific needs.

FAQ

1. Are oil-free air compressors more expensive?

While oil-free models might have a slightly higher upfront cost, their reduced maintenance requirements and longer lifespan often make them more cost-effective in the long run.

2. Can I use an oil-free air compressor for spray painting?

Yes, oil-free compressors are ideal for spray painting as they ensure a clean, oil-free finish.

3. How often should I drain the moisture from my oil-free compressor?

It’s recommended to drain the moisture daily or after each use, especially in humid environments.

4. Can I use an oil-free air compressor for medical purposes?

For sensitive medical applications, consult with a healthcare professional and choose a compressor specifically designed and certified for medical use.

5. How long do oil-free air compressors last?

With proper maintenance, oil-free air compressors can last for many years, often exceeding the lifespan of oil-lubricated models.

Looking for the Quietest and Most Efficient Oil-Free Air Compressor?

Check out our in-depth review of quiet oil free air compressor for the ultimate solution to your compressed air needs!

Need more information on air compressors and their applications?

Explore our website for comprehensive guides on various compressor types, maintenance tips, and expert advice to help you make the right choice.

Contact us for personalized assistance:

Phone: 0972669017

Email: [email protected]

Address: 142 Trần Nhân Tông, Yên Thanh, Uông Bí, Quảng Ninh, Vietnam

Our dedicated customer support team is available 24/7 to answer your queries and provide expert guidance.