Lead-free solder flux is a crucial component in modern soldering processes, especially in electronics where lead-free alternatives are mandated for health and environmental reasons. This guide delves into the intricacies of lead-free solder flux, exploring its functions, types, and best practices for achieving optimal results.

What is Lead-Free Solder Flux?

Lead-free solder flux is a chemical cleaning agent used in soldering to facilitate the bonding process between metals. Unlike traditional lead-based solders, lead-free solder flux is formulated to work at higher temperatures, typically above 217°C (423°F), which is necessary to melt lead-free solder alloys.

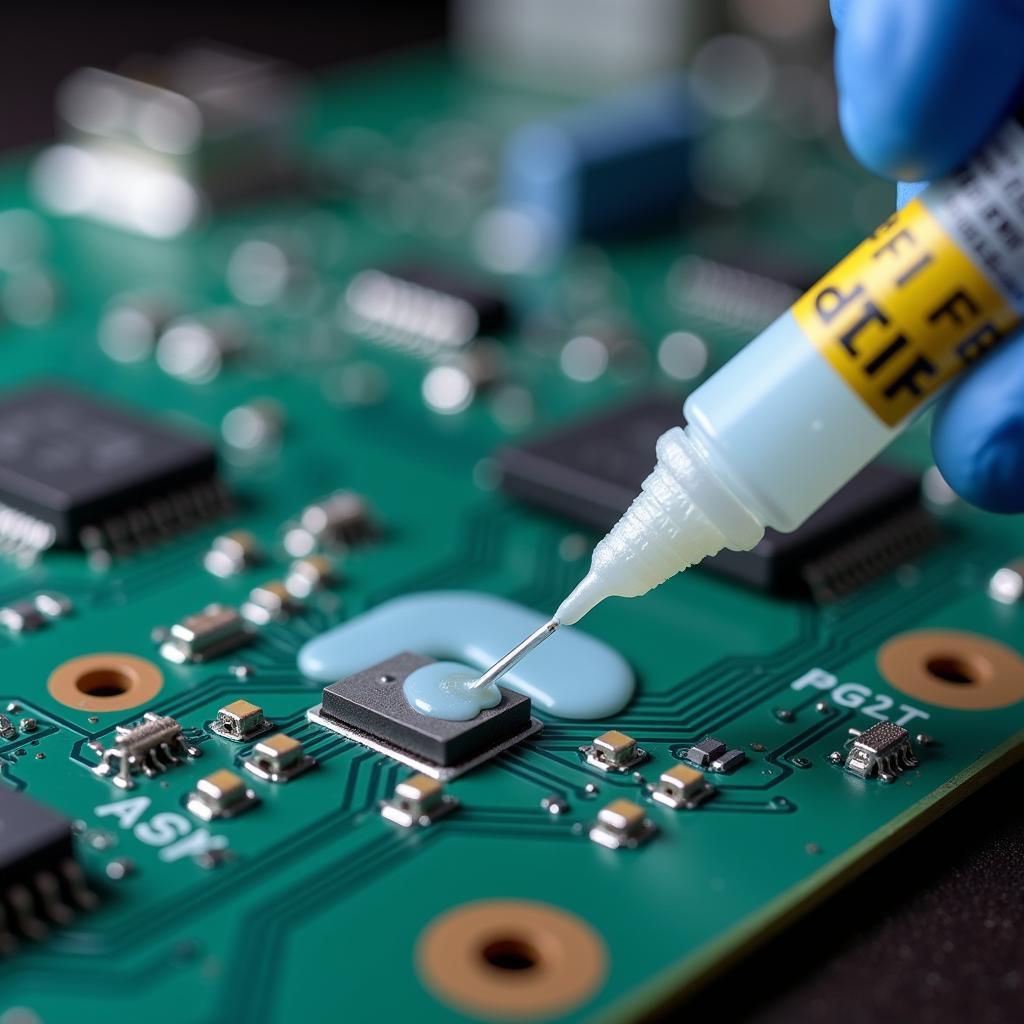

Applying Lead-Free Solder Flux

Applying Lead-Free Solder Flux

The primary function of lead-free solder flux is to remove oxides and other contaminants from the metal surfaces being joined. This is critical because oxides can prevent the solder from properly wetting and adhering to the metal, leading to weak and unreliable joints.

Why is Lead-Free Solder Flux Important?

Lead-free solder flux is essential for several reasons:

- Environmental Protection: Lead is a toxic heavy metal that can contaminate soil, water, and air, posing serious health risks. Using lead-free alternatives minimizes environmental impact and promotes sustainability.

- Health and Safety: Lead exposure can lead to various health problems, especially in children. Lead-free solder flux eliminates this risk, creating a safer working environment for electronics manufacturers and consumers.

- Improved Solder Joint Reliability: Lead-free solder flux is specifically designed to work with lead-free solder alloys, which tend to have different melting points and flow characteristics. This ensures strong and durable solder joints in electronic devices.

Types of Lead-Free Solder Flux

Lead-free solder fluxes are categorized based on their activity levels and chemical compositions:

1. Rosin Flux

- Activity Level: Low to medium

- Residue: Non-corrosive and generally non-conductive but may require cleaning for sensitive electronics.

- Applications: Ideal for general electronics soldering, hobby projects, and situations where residue removal is not critical.

2. Water-Soluble Flux

- Activity Level: Medium to high

- Residue: Corrosive and requires cleaning after soldering to prevent damage to the electronic components.

- Applications: Suitable for soldering oxidized metals, stainless steel, and situations requiring stronger cleaning action.

3. No-Clean Flux

- Activity Level: Low to medium

- Residue: Non-corrosive, non-conductive, and designed to be left on the board without cleaning.

- Applications: Widely used in high-volume electronics manufacturing where cleaning is not practical or feasible.

How to Choose the Right Lead-Free Solder Flux

Selecting the appropriate lead-free solder flux depends on several factors:

- Type of Metal: The type of metal being soldered influences the flux’s effectiveness.

- Solder Alloy: Different lead-free solder alloys have varying melting points and require compatible fluxes.

- Application: The intended use of the soldered component, such as in high-frequency or high-voltage applications, dictates the flux’s properties.

- Cleaning Requirements: Consider whether post-soldering cleaning is feasible or if a no-clean flux is preferred.

Soldering Iron and Flux Types

Soldering Iron and Flux Types

Lead-Free Solder Flux: Best Practices

Follow these tips for effective soldering with lead-free solder flux:

- Cleanliness is Key: Ensure all surfaces to be soldered are clean and free of dirt, grease, and oxides. Use appropriate cleaning agents like isopropyl alcohol.

- Apply Flux Sparingly: A thin, even layer of flux is sufficient. Excess flux can lead to soldering defects and require additional cleaning.

- Use the Right Temperature: Lead-free solders require higher temperatures. Adjust your soldering iron accordingly and refer to the solder’s datasheet for recommended temperatures.

- Don’t Overheat: Excessive heat can damage components and degrade the flux’s effectiveness. Apply heat only as long as needed to melt the solder and form a good joint.

- Clean Residues When Necessary: For corrosive fluxes, thoroughly clean the soldered area after soldering using appropriate cleaning solutions and techniques.

- Store Flux Properly: Store lead-free solder flux in a cool, dry place to prevent degradation and maintain its effectiveness.

Frequently Asked Questions about Lead-Free Solder Flux

1. Can I use lead-free solder flux with lead-based solder?

While it’s technically possible, it’s not recommended. Lead-free and lead-based solders have different melting points and flow characteristics. Using the wrong flux can result in poor solder joints.

2. Is all lead-free solder flux no-clean?

No, not all lead-free solder fluxes are no-clean. Rosin and water-soluble fluxes require cleaning after soldering.

3. What are the health risks associated with lead-free solder flux?

Lead-free solder fluxes are generally considered safer than lead-based fluxes. However, it’s always advisable to work in a well-ventilated area and avoid contact with skin and eyes. Refer to the flux’s safety data sheet for specific precautions.

4. Can I make my own lead-free solder flux?

While it’s possible to find DIY recipes for solder flux, it’s not recommended, especially for critical applications. Commercially available fluxes are formulated for consistency and performance.

5. How long does lead-free solder flux last?

The shelf life of lead-free solder flux varies depending on the type and storage conditions. Check the manufacturer’s recommendations for specific storage and expiration information.

Conclusion

Lead-free solder flux plays a vital role in ensuring the reliability and safety of electronic devices. Choosing the right type of flux and following best practices are crucial for achieving optimal soldering results. By understanding the different types of lead-free solder flux and their applications, you can make informed decisions for your soldering projects.

For those seeking more specific guidance, consider exploring related topics like “free stained glass hummingbird patterns” or “lead-free stained glass solder” for insights into different soldering applications and materials.

If you need further assistance with lead-free soldering or related topics, please don’t hesitate to contact us at 0972669017 or [email protected]. Our team of experts is available 24/7 to answer your questions and provide support. You can also visit us at our office located at 142 Trần Nhân Tông, Yên Thanh, Uông Bí, Quảng Ninh, Việt Nam.